- Phone: +(675) 7568 9790

Premier Concrete Services Limited is a fully computerized CIFA wet concrete batching plant delivering capabilities of 120m3 per hour delivering high quality consistent MPA strength and currently delivery 60m3 per hour to customers.

Not only MPA strength certifications but including all materials used to produce the product, which includes, bore water, coarse sand and aggregates (10mm, 14mm, and 20mm). All materials are gone through Cardno (PNG) Limited for certification after every 6 months.

The batching plant and the staff are trained and certified through Cardno (PNG) Limited to do slump testing and Compression Cylinders for Crush Testing 7,14,28,56 on batch plant site.

Cardno Technician doing test on batch plant site. QAA

Cardno Lab Manager testing PCL employees do slump testing and cylinder for Certification.

Slump testing for cylinder. QAA

Premier Concrete Services Limited uses third party when it comes to reports, certificates and testing through Cardno (PNG) Limited as we work under Australian Standards.

We employ several Australian, New Zealand & British expatriate executive & technical managers. Primarily to operate, train and oversee the business. All with greater than 20 year’s full time experience in PNG or their related field.

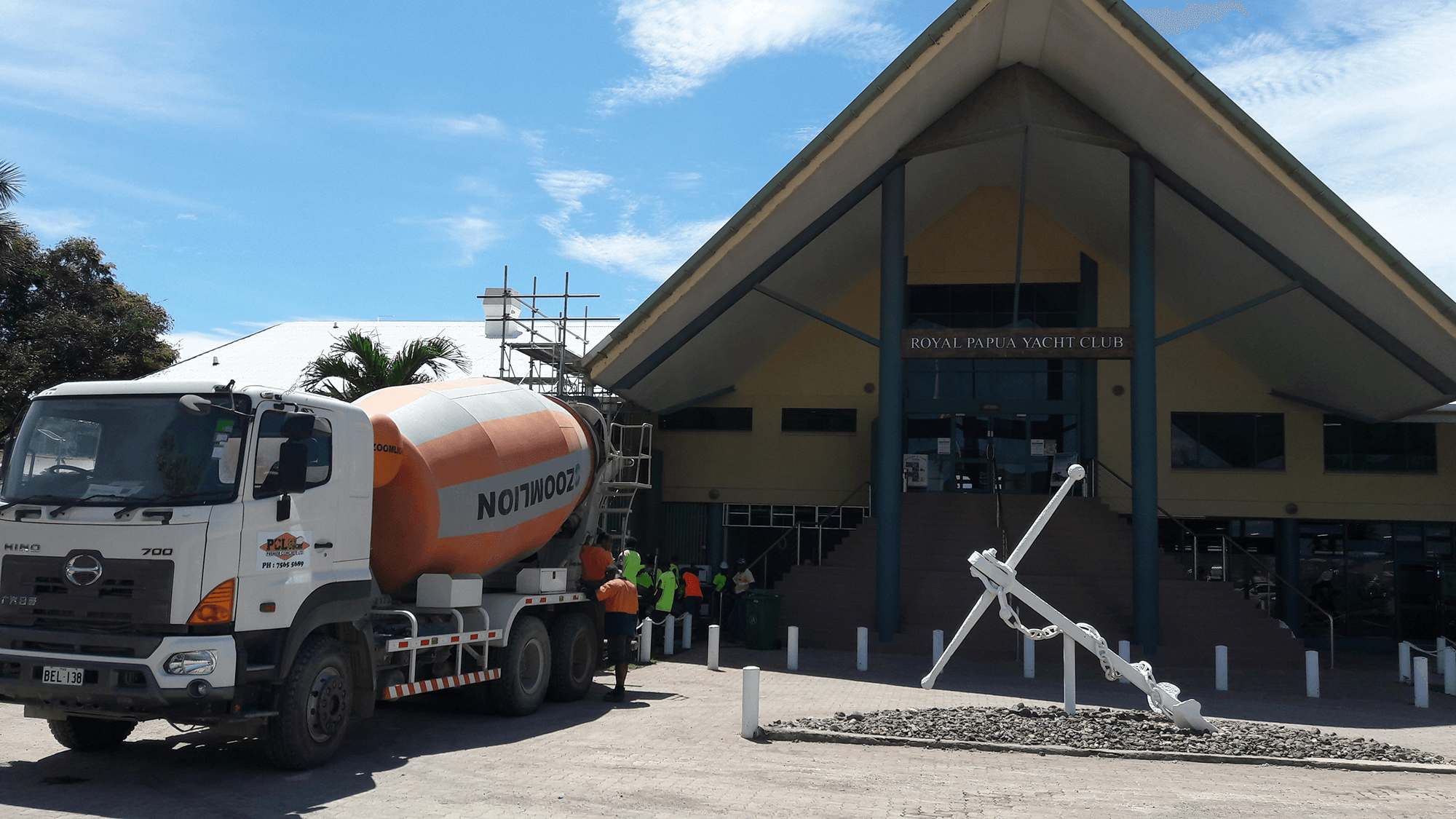

Proven in providing bulk concrete with early high MPA strength in helping big projects move forward to achieve and complete projects on time required. Both structural and Pump mixes.

Premier Concrete Services Limited has been providing concrete for 3 years in building infrastructure and roads throughout Port Moresby. We are specialized in doing Kerb Mixing for roads constructions as we are the only batching plant in Port Moresby that provides wet Kerb Mix.

We are also certified by NCD City Authorities to do concrete roads and public car parks, PNG Power Engineers to supply concrete for Transmission Towers Foundations within the city of Port Moresby. As we have once again proven in our high early MPA concrete strength.

Premier Concrete Services also is a supplier of Pre-cast Road Barrier system unit dimensions 2.4m x 1.0m.

| NO | MIX ID | Description |

| 20mm Mixes | ||

| 1 | 1020S | 10MPa 20mm Stnd |

| 2 | 1520S | 15MPa 20mm Stnd |

| 3 | 1720S | 17.5MPa 20mm Struct Stnd |

| 4 | 2020S | 20MPa 20mm Struct Stnd |

| 5 | 2520S | 25MPa 20mm Struct Stnd |

| 6 | 3220S | 32MPa 20mm Struct Stnd |

| 7 | 3520S | 35MPa 20mm Struct Stnd |

| 8 | 4020S | 40MPa 20mm Struct Stnd |

| 9 | 4520S | 45MPa 20mm Struct Stnd |

| 10 | 5020S | 50MPa 20mm Struct Stnd |

| 14mm Mixes | ||

| 11 | 1014S | 10MPa 14mm Stnd |

| 12 | 1514S | 15MPa 14mm Stnd |

| 13 | 1714S | 17.5MPa 14mm Struct Stnd |

| 14 | 2014S | 20MPa 14mm Struct Stnd |

| 15 | 2514S | 25MPa 14mm Struct Stnd |

| 16 | 3214S | 32MPa 14mm Struct Stnd |

| 17 | 3514S | 35MPa 14mm Struct Stnd |

| 18 | 4014S | 40MPa 14mm Struct Stnd |

| 19 | 4514S | 45MPa 14mm Struct Stnd |

| 20 | 5014S | 50MPa 14mm Struct Stnd |

| 10mm Mixes | ||

| 21 | 1010S | 10MPa 10mm Stnd |

| 22 | 1510S | 15MPa 10mm Stnd |

| 23 | 1710S | 17.5MPa 10mm Struct Stnd |

| 24 | 2010S | 20MPa 10mm Struct Stnd |

| 25 | 2510S | 25MPa 10mm Struct Stnd |

| 26 | 3210S | 32MPa 10mm Struct Stnd |

| 27 | 3510S | 35MPa 10mm Struct Stnd |

| 28 | 4010S | 40MPa 10mm Struct Stnd |

| 29 | 4510S | 45MPa 10mm Struct Stnd |

| 30 | 5010S | 50MPa 10mm Struct Stnd |

| Pump Mixes 20mm | ||

| 31 | 3220P | 32MPa 20mm Struct Pump |

| 32 | 3520P | 35MPa 20mm Struct Pump |

| 33 | 4020P | 40MPa 20mm Struct Pump |

| 34 | 4520P | 45MPa 20mm Struct Pump |

| 35 | 5020P | 50MPa 20mm Struct Pump |

| Pump Mixes 14mm | ||

| 36 | 3214P | 32MPa 14mm Struct Pump |

| 37 | 3514P | 35MPa 14mm Struct Pump |

| 38 | 4014P | 40MPa 14mm Struct Pump |

| 39 | 4514P | 45MPa 14mm Struct Pump |

| 40 | 5014P | 50MPa 14mm Struct Pump |

| Pump Mixes 10mm | ||

| 41 | 3210P | 32MPa 10mm Struct Pump |

| 42 | 3510P | 35MPa 10mm Struct Pump |

| 43 | 4010P | 40MPa 10mm Struct Pump |

| 44 | 4510P | 45MPa 10mm Struct Pump |

| 45 | 5010P | 50MPa 10mm Struct Pump |